I am Subhendu Chakraborty, post-doctoral researcher at the Los Alamos National Laboratory (LANL) in the field of computational modeling of metallic material at continuum and atomistic scales.

I am Subhendu Chakraborty, post-doctoral researcher at the Los Alamos National Laboratory (LANL) in the field of computational modeling of metallic material at continuum and atomistic scales.

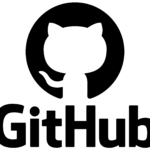

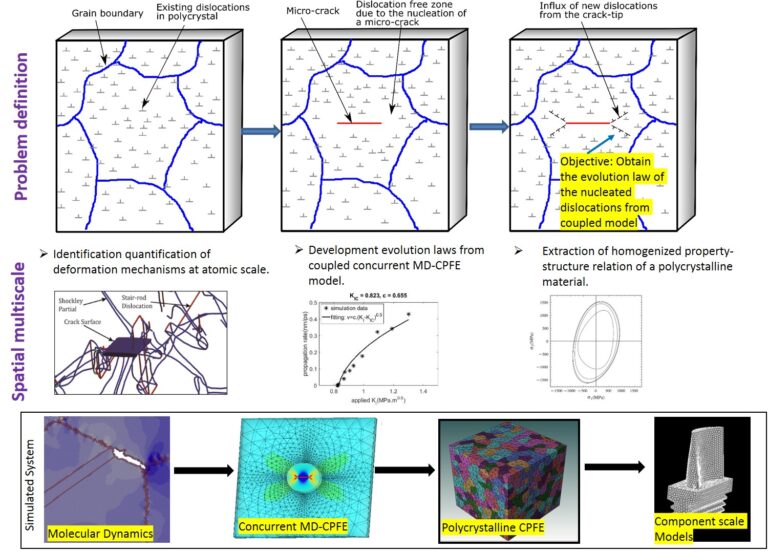

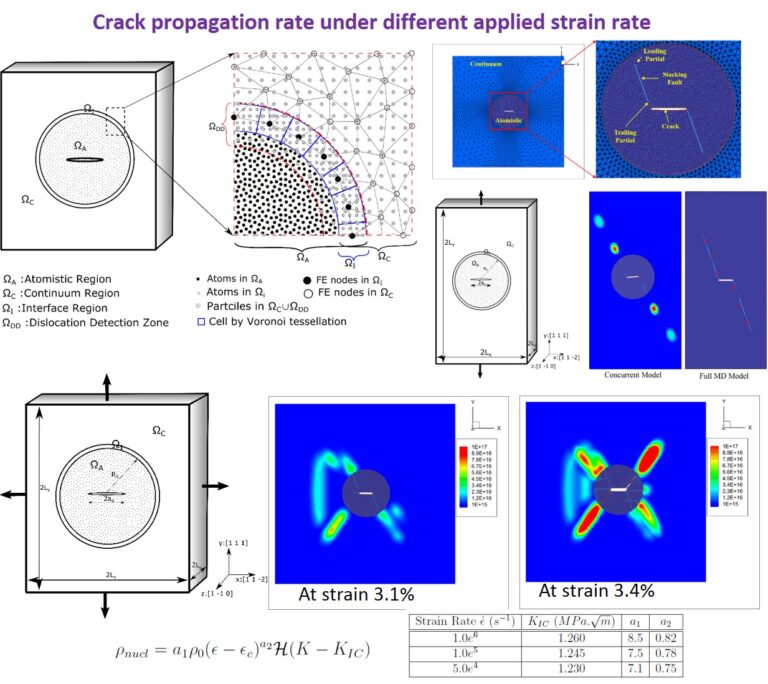

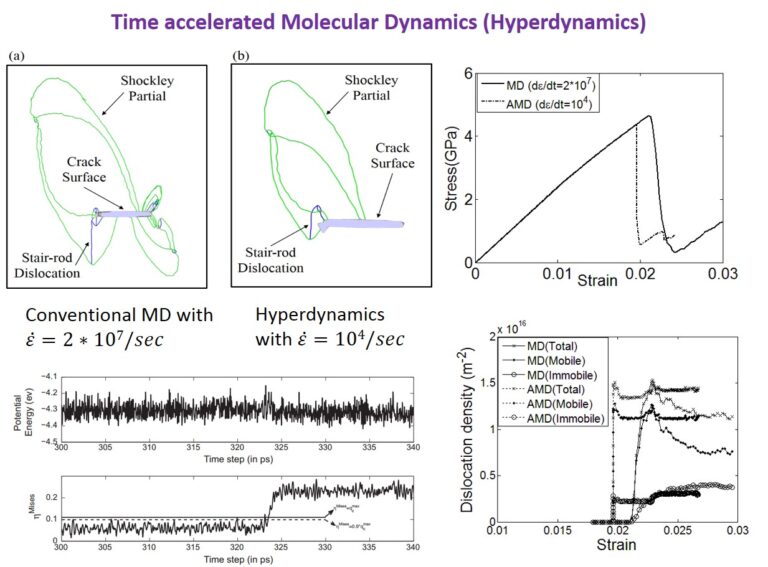

I have completed my Ph.D in the Department of Mechanical Engineering of Johns Hopkins University. During my Ph.D., I have worked extensively in the realm of atomistic modeling of metallic materials using Accelerated Molecular Dynamics. I have developed a concurrent multiscale model by coupling Molecular Dynamics(MD) with density-based Crystal Plasticity(CPFE) to extend the spatial scale of the atomistic model. For MD model, I have used LAMMPS and also incorporated new features into the LAMMPS for the time acceleration(Hyperdynamics) of the MD model.

During my postdoc, at Los Alamos National Laboratory, I am developing a dislocation transport-based crystal plasticity model that incorporates the dislocation transport within the grain and across the grain boundary. The model is useful to study the interaction of dislocations with grain boundary in polycrystalline materials and it’s macroscopic implication in the deformation behavior of the material. I have implemented the model into the open-source code MOOSE. The process involves developing crystal plasticity material class, different volumetric kernels, boundary kernels, interface kernels and auxkernels. Also some base-classes for array variables. The code is in the process of obtaining permission from NNSA for open source release

Tags: CPFE, MOOSE, MD, AMD, LAMMPS, Metal Plasticity, Defect Interaction, Phase Field, Meshless RKPM, XFEM

My research EXPERIENCES include:

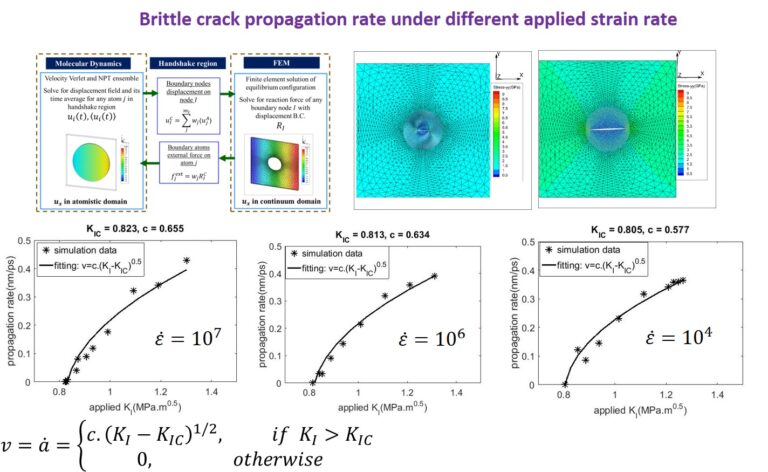

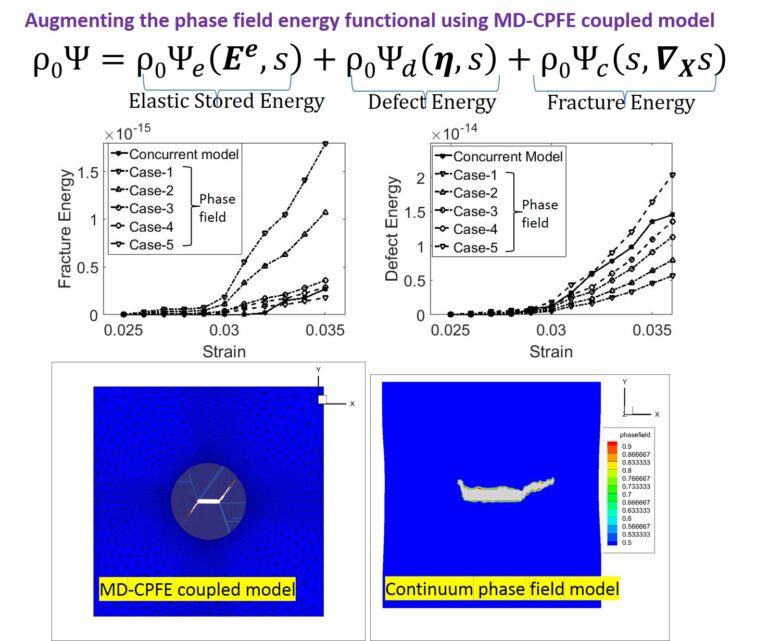

- Atomistic-Continuum coupled multiscale model: Development of a concurrent model by coupling Crystal Plasticity Finite Element(CPFE) and Molecular Dynamics(MD). Extraction of defect evolution laws and phase field energy functional by using the coupled model for higher scale continuum fracture models.

- Time-accelerated Molecular Dynamics: Incorporation of time-scale acceleration (strain boost Hyperdynamics) in MD for a longer time and hence low strain rate based MD simulation.

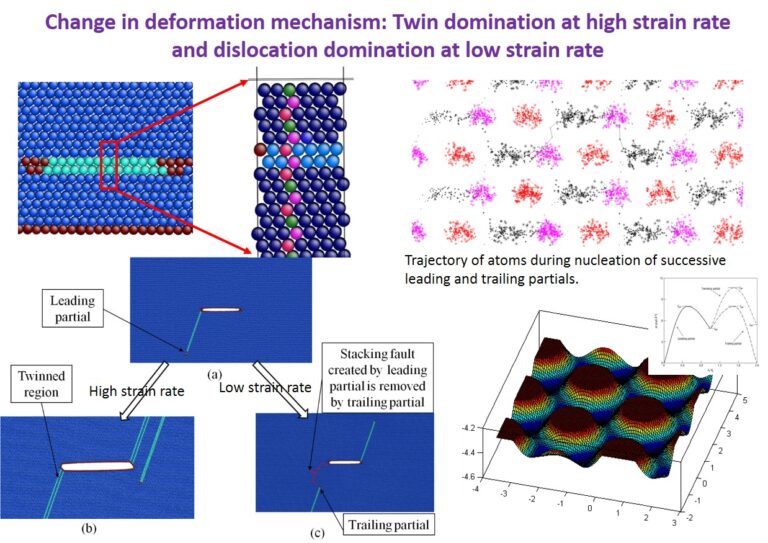

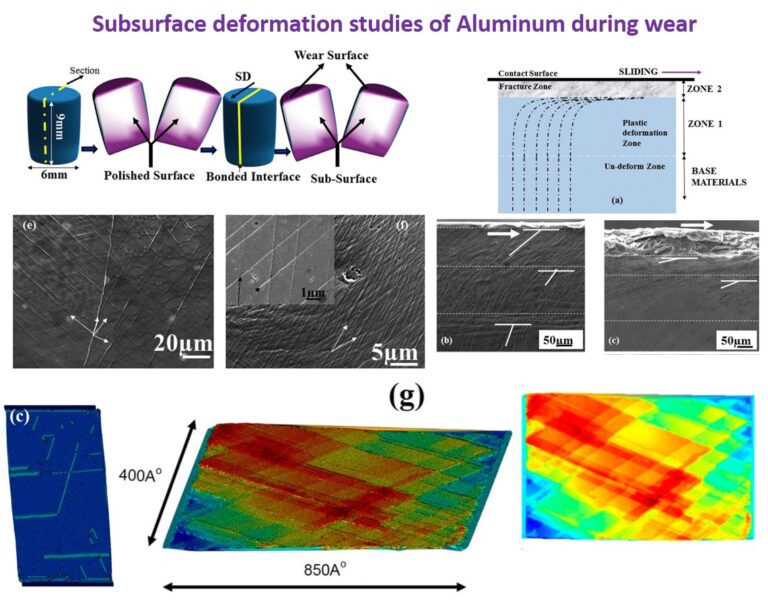

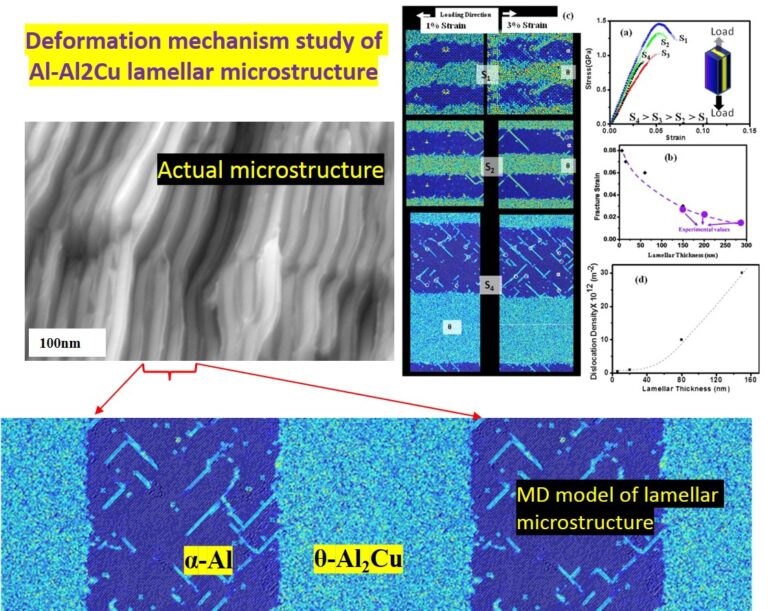

- Deformation Mechanisms of materials: Characterization and quantification of different deformation mechanisms of structural materials at the atomic scale.

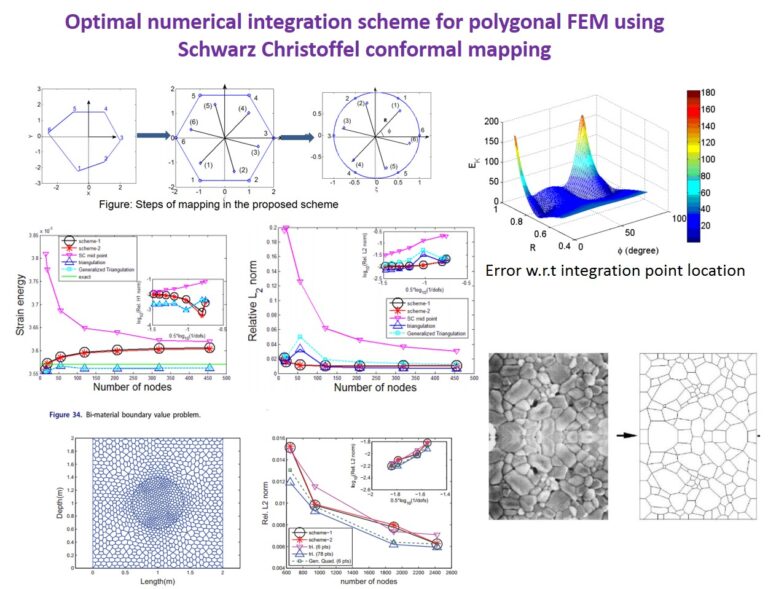

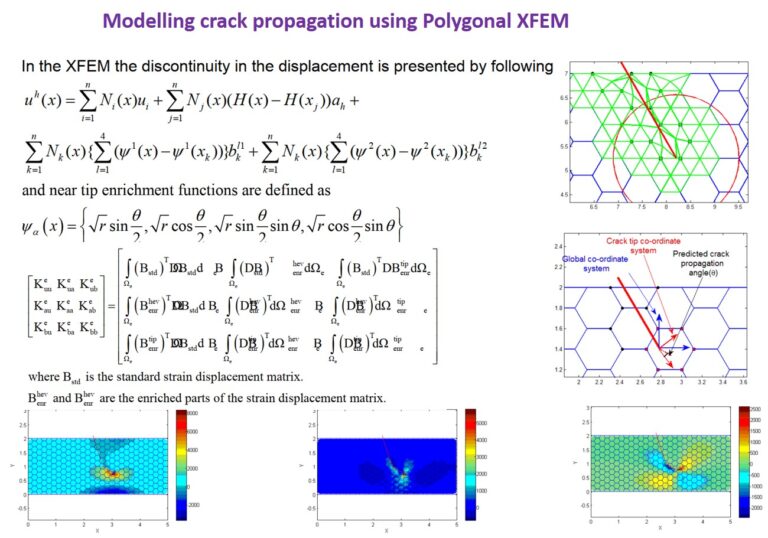

- Polygonal XFEM: Modeling the crack propagation in 2D using polygonal XFEM.

**More in “My Research” page.

My research INTERESTS include but not limited to:

- Problem specific coupled atomistic (MD/MS) continuum (CPFE/DD) model development to extend the spatial and temporal scale of the classical atomistic simulation.

- Atomic-scale investigation of deformation mechanisms and defect interactions using time-accelerated MD or multiscale model.

- Effect of alloying elements on the mechanical properties of structural materials using time-accelerated MD.

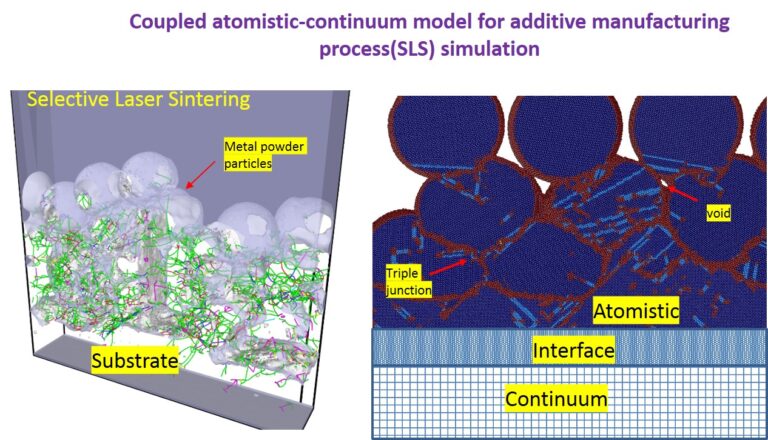

- A moving-interface multiscale model for additive manufacturing (SLS) process by coupling CPFE (DD or other continuum model) with MD to predict the grain microstructure and defect-structure under different process parameters.

- Or any other…..

All researches in one place: “My Research“

Ph.D. Thesis: here

Masters Thesis: here

My CV: here

(last updated: Feb2021)

ORCiD: 0000-0002-5685-3630

WOS ID: HMD-8963-2023